PROFICUT SRKS FLATBED CUTTING PLOTTER

PROFICUT SRKS

✓ Quality cutting at high speeds thanks to all-welded frame

✓ Possibility to mount 1 to 3 tangential tools on the carriage

✓ A wide range of modules and tools for the most efficient operation

✓ High productivity up to 60 m/min

✓ High precision aluminum table with conveyor system for ease of use

✓ Powerful material clamping system with power adjustment in the cutting zone for more precise work

✓ Ideal for cutting sheet and roll materials

----

Performance up to 1m/sec

Warranty 2 years

Intuitive software

Commissioning and training included in the price

Cutting accuracy 0.15 mm

COMPETENT SOLUTIONS FOR POPULAR BUSINESS AREAS

PACKAGING PRODUCTION

Corrugated cardboard, boxboard, spoons, protective packaging

ADVERTISING AND PRINTING

Signboards, interior signs (signs and directional signs), POP constructions, mobile stands

TEXTILE INDUSTRY

Professional patterns and templates on paper, labeling, fabric and leather cutting

AUTOMOTIVE INDUSTRY

Car seat upholstery, car mats, noise insulation, protective curtains and covers, awnings, car hammocks Professional cutouts and patterns on paper, marking, cutting of fabric and leather

TRAVEL EQUIPMENT

Tents, mats, sleeping bags, kites, sails, inflatable pools and boats

ADVANTAGES OF PROFICUT CUTTING MACHINES

PRECISION MECHANICS

The portal movement is achieved through two independent Mitsubishi servo motors, synchronized by the machine's control electronics. The movements along the axes are facilitated by a helical gear transmission mechanism

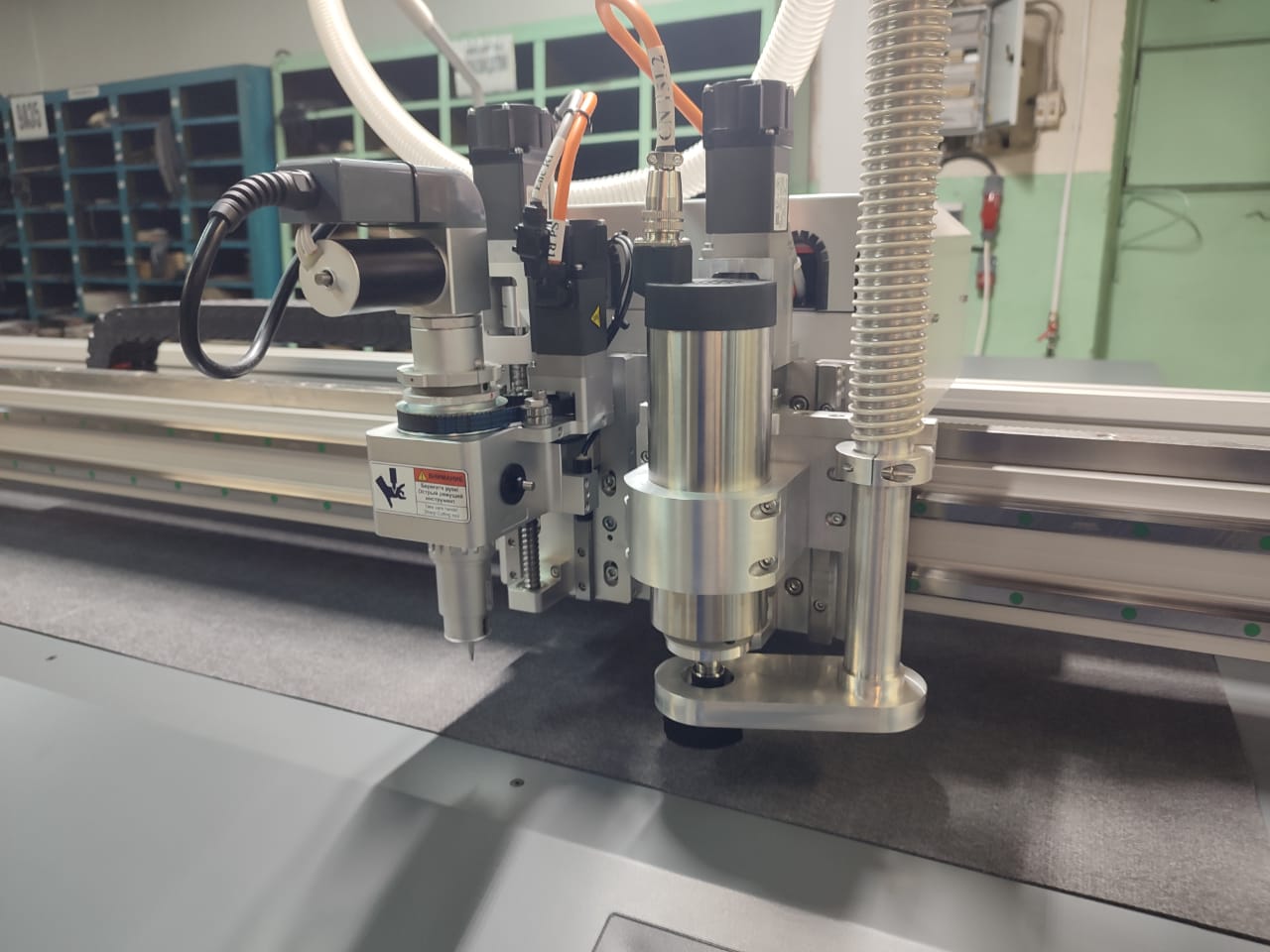

MOUNTING 1 TO 3 TOOLS ON CARRIAGES

The functional feature of the equipment allows for the installation of up to 3 tools on the carriage

INTEGRATED ROLL-FEED SYSTEM

For precise feeding of roll material onto the conveyor table

INTELLIGENT CONVEYOR TABLE

To ensure continuous material feeding to the working area of the machine, which reduces downtime by 2 times, minimizes costs, and increases productivity by 80%

VACUUM TABLE WITH A ZONED CLAMPING DEVICE

The aluminum vacuum table with the "smart" zoning function allows for material clamping with adjustable vacuum levels according to the type and nature of the material

OPTICAL SCANNING SYSTEM (CAMERA)

For precise material positioning during cutting based on a printed image

INTEGRATION WITH VECTOR PROGRAMS

The preparation of cutting layouts can be done in any vector editing software that supports export in PLT, DXF, or G-code format

OPTIMIZATION WITH SKY TECH UV PRINTER

Integration with SKY TECH UV printers for optimizing printing and cutting of images on popular materials

AVAILABLE TOOLS FOR PROFICUT

| PNEUMATIC OSCILLATING TOOL (PNOT)

| |

| ELECTRIC OSCILLATING TOOL 600 WATT. (ELOT)

The ELOT is the perfect choice for precise and fast cutting of materials up to 30mm thick. With its oscillating blade motion, the ELOT ensures high precision and cutting speed, eliminating material jamming between the blade and the cutting surface. Lightweight and easy to use, the ELOT is an ideal tool for those seeking a simple and efficient way to cut materials. With a wide selection of blades available, it is easy to find the optimal knife for each material, including paper, PVC film, leather, rubber, and corrugated cardboard. | |

| KISS CUT TOOL

The Kiss Cut tool is a versatile solution for fast and high-quality cutting of various materials such as PVC film, reflective materials, paper, thin cardboard, magnetic vinyl, and other roll materials. With this tool, it is easy to create precise kiss cuts, which allow for easy separation of cut parts from the backing material. Kiss Cut is a reliable assistant for the production of various products from roll materials. | |

| ROTARY CUTTING TOOL (RTCT)

RTCT is a cutting tool designed for efficient cutting of various types of textiles and PVC fabrics. It is also suitable for processing materials such as Kevlar, fiberglass, and carbon fiber. Our technology ensures precision and quality cutting, allowing for reduced production costs and increased productivity. We guarantee the reliability and durability of our tool, making it an ideal choice for any material cutting task. | |

| CUTTING TOOL FOR CUTTING ANGLES 0°,15°,22.5°, 30°,45° (VCUT)

The VCUT cutting tool is designed for cutting at angles of 0°, 15°, 22.5°, 30°, and 45°. It is ideal for cutting complex structural forms such as rigid sandwich panels and foamed composite materials. With VCUT, you will be able to quickly and easily create high-quality and precise cuts, significantly speeding up the production process and enhancing its efficiency. | |

| MARKING TOOL

It is the perfect solution for those looking for a way to apply graphic information or labeling onto their products. | |

| MODULE.HOLE PUNCH (POT)

The modular puncher, POT, is an efficient solution for creating holes with diameters ranging from 1 to 6 mm. It is perfect for punching perforations in fabric and leather products. With POT, you can easily and quickly create holes of the desired diameter without damaging the material. This tool will definitely be useful when working with textile and leather goods. | |

| CREASING TOOL WITH 3 WHEEL DIAMETERS (BTD)

The BTD tool features three wheel diameters and is used for creating linear grooves on soft materials such as cardboard. It is perfect for creating grooves that can be easily folded afterwards. This tool consists of an attachment with a movable roller, ensuring more precise and even application of the line. BTD is a reliable and efficient solution for anyone working with soft materials and seeking a quick and easy way to create grooves. | |

| UNIVERSAL TANGENTIAL CUTTING TOOL (UTCT)

UTCT is a universal tangential cutting tool that provides an optimal solution for cutting materials up to a thickness of 5mm. This tool is ideal for cutting films, cardboard, and thin plastics. Due to its versatility, UTCT can be used in various industries such as packaging manufacturing, advertising and design studios, and other areas where precise and high-quality material cutting is required. UTCT is a reliable and high-quality tool that will help you tackle any material cutting task with ease. | |

| MILLING UNIT. MILLING TOOL (FRT)

The milling module with the Milling Tool (FRT) is an innovative solution for processing rigid materials such as acrylic, composite, and ABS plastic. The spindle provides a speed of up to 24,000 revolutions per minute, allowing for cutting materials up to 20mm thick. We offer two models of FRT: with power of 0.8 kW and 1.8 kW. These models ensure high precision and productivity when processing materials. The milling module with the Milling Tool (FRT) is a reliable and efficient solution for your production needs. It is perfect for processing various materials and can be used in different industries such as furniture manufacturing, advertising, and interior design. |

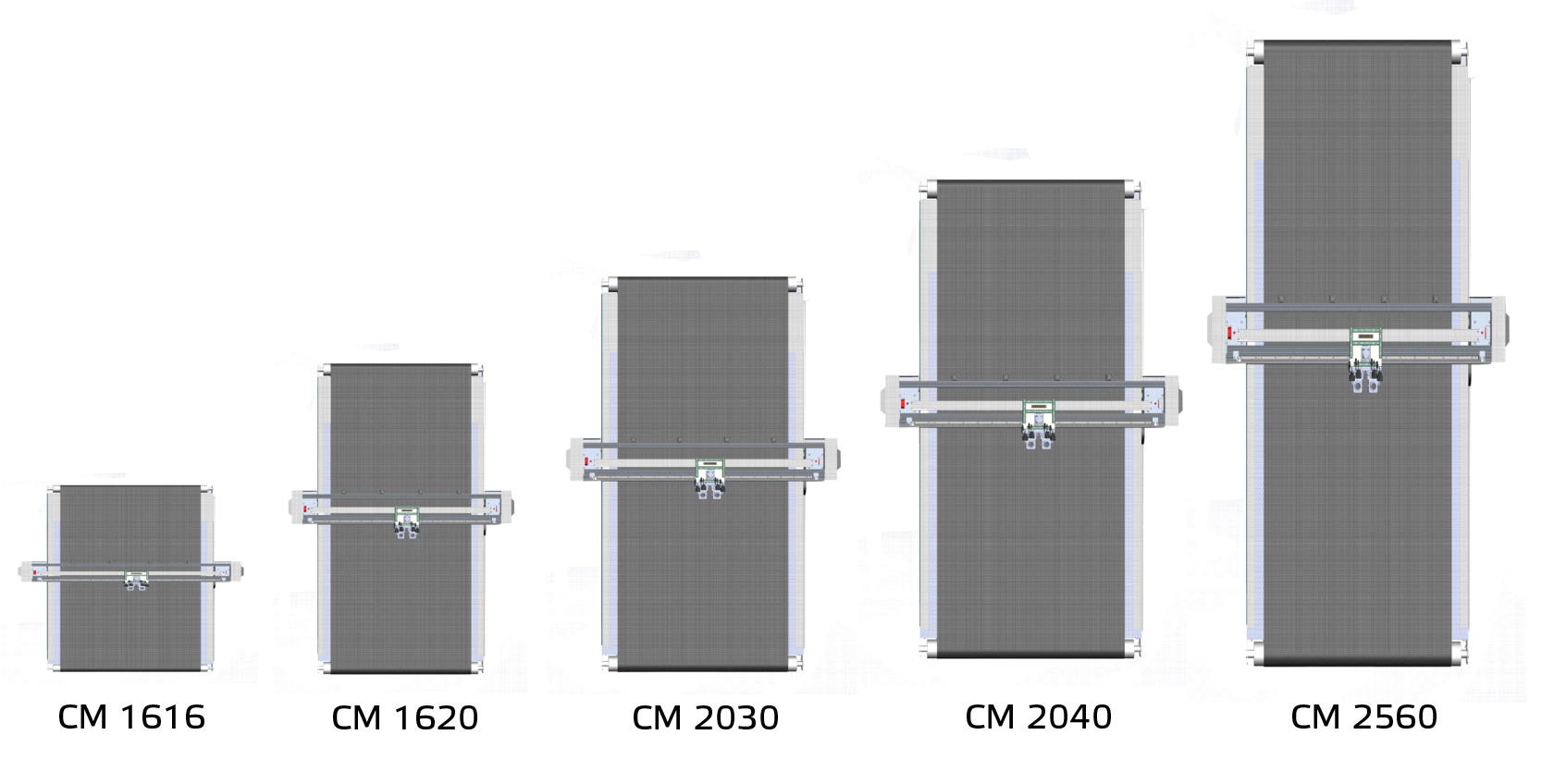

WORKSPACE OPTIONS

A flatbed cutting plotter is a solution that can be used in various industries. One of the main advantages of this device is its wide selection of working areas. Depending on the production needs, the plotter's working areas can range from small 1600x1300mm to huge 2500x6000mm. This means that the plotter can process both small and large sheets of materials.

A flatbed cutting plotter is a solution that can be used in various industries. One of the main advantages of this device is its wide selection of working areas. Depending on the production needs, the plotter's working areas can range from small 1600x1300mm to huge 2500x6000mm. This means that the plotter can process both small and large sheets of materials.---

CUTTING CARPET ON A PROFICUT FLATBED CUTTING PLOTTER

CUTTING CORRUGATED CARDBOARD ON A PROFICUT FLATBED CUTTING PLOTTER

CUTTING FABRIC ON A PROFICUT FLATBED CUTTING PLOTTER

CUTTING THICK RUBBER ON THE PROFICUT FLATBED CUTTING PLOTTER

CUTTING OF TECHNICAL FABRIC ON A PROFICUT FLATBED CUTTING PLOTTER

CUTTING OF HONEYCOMB CARDBOARD ON A PROFICUT FLATBED CUTTING PLOTTER

CUTTING OF LEATHER. CUTTING ON PROFICUT FLATBED CUTTING PLOTTER

CUTTING VENEER ON PROFICUT FLATBED CUTTING PLOTTER

CUTTING TARPAULIN FABRIC ON A PROFICUT FLATBED CUTTING PLOTTER

CUTTING REINFORCED RUBBER ON A PROFICUT FLATBED CUTTING PLOTTER

CUTTING EVA MATERIAL ON THE PROFICUT FLATBED CUTTING PLOTTER

PVC FILM CUTTING ON PROFICUT FLATBED CUTTING PLOTTER

MILLING OF PLEXIGLASS 10 MM. V-SHAPED MILLING CUTTER ON A FLATBED CUTTING PLOTTER

One of the key features of this plotter is the ability to install a conveyor table, which increases productivity by automatically loading and unloading pre-cut material parts. This feature is especially useful for large-scale production.

Additionally, the ProfiCut can be equipped with a passive loading system for roll materials onto the working area. This simplifies the process of material loading onto the plotter and makes it easier for operators to work.

Another interesting feature of the plotter is the option to install a projection system for cutting natural leather with automatic spreading functionality. This enables quick and easy identification of the optimal leather positioning for cutting, significantly enhancing precision and speed.

The dimensions of the ProfiCut are also impressive. This plotter is available in sizes of 1600x1300mm, 1600x2000mm, 1300x2600mm, and 2000x3000mm, making it suitable for companies of any size.

ProfiCut from the SRKS series is a powerful and reliable equipment with high performance, which can help your company optimize production processes and increase efficiency. If you're looking for quality industrial equipment, ProfiCut is an excellent choice!