Glass and mirror cutting machines

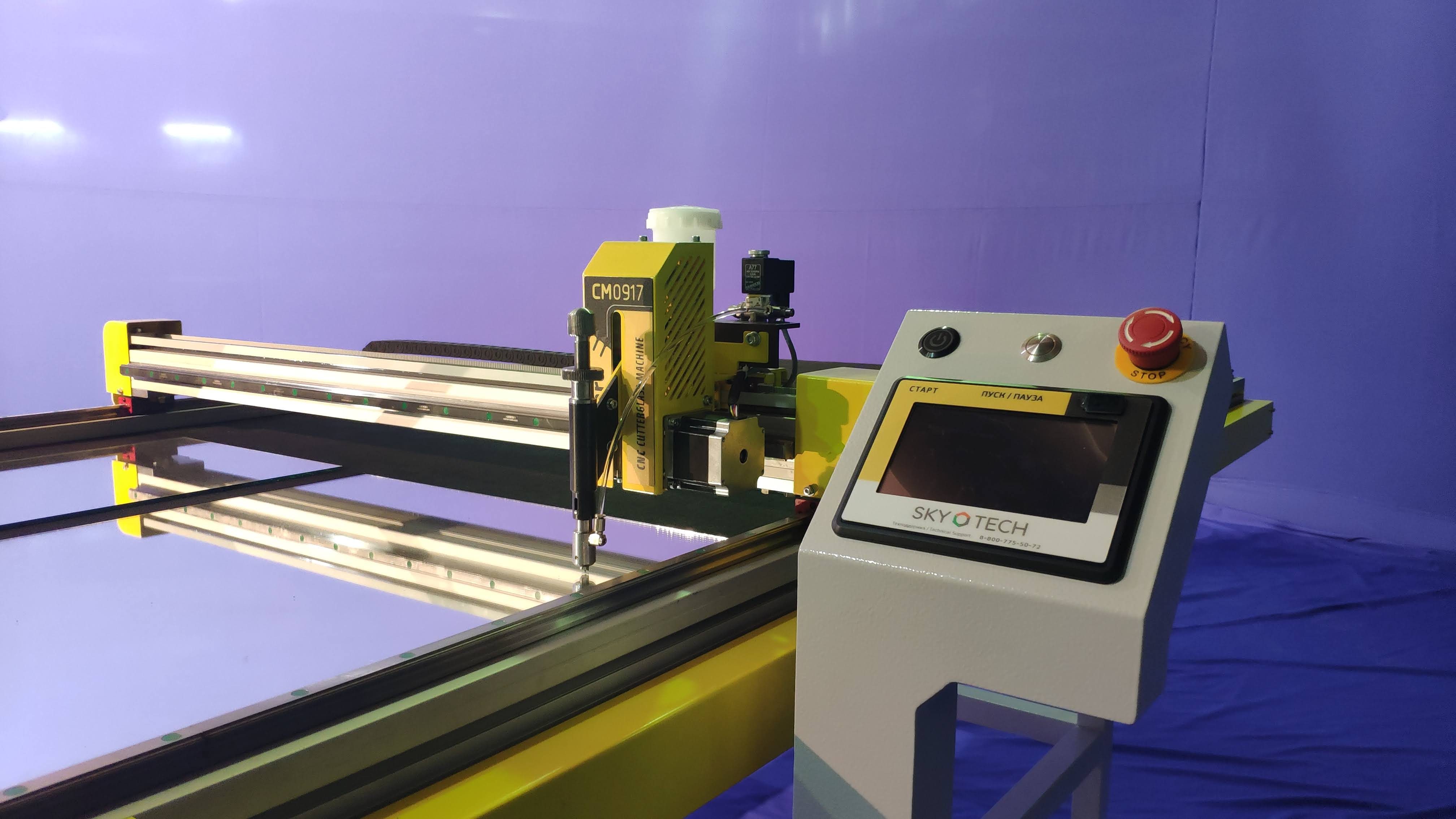

LEOPARD GLASS CUTTING MACHINE

The Leopard series glass cutting machine is a budget-friendly yet highly efficient solution for cutting glass with thicknesses ranging from 2 to 10mm.

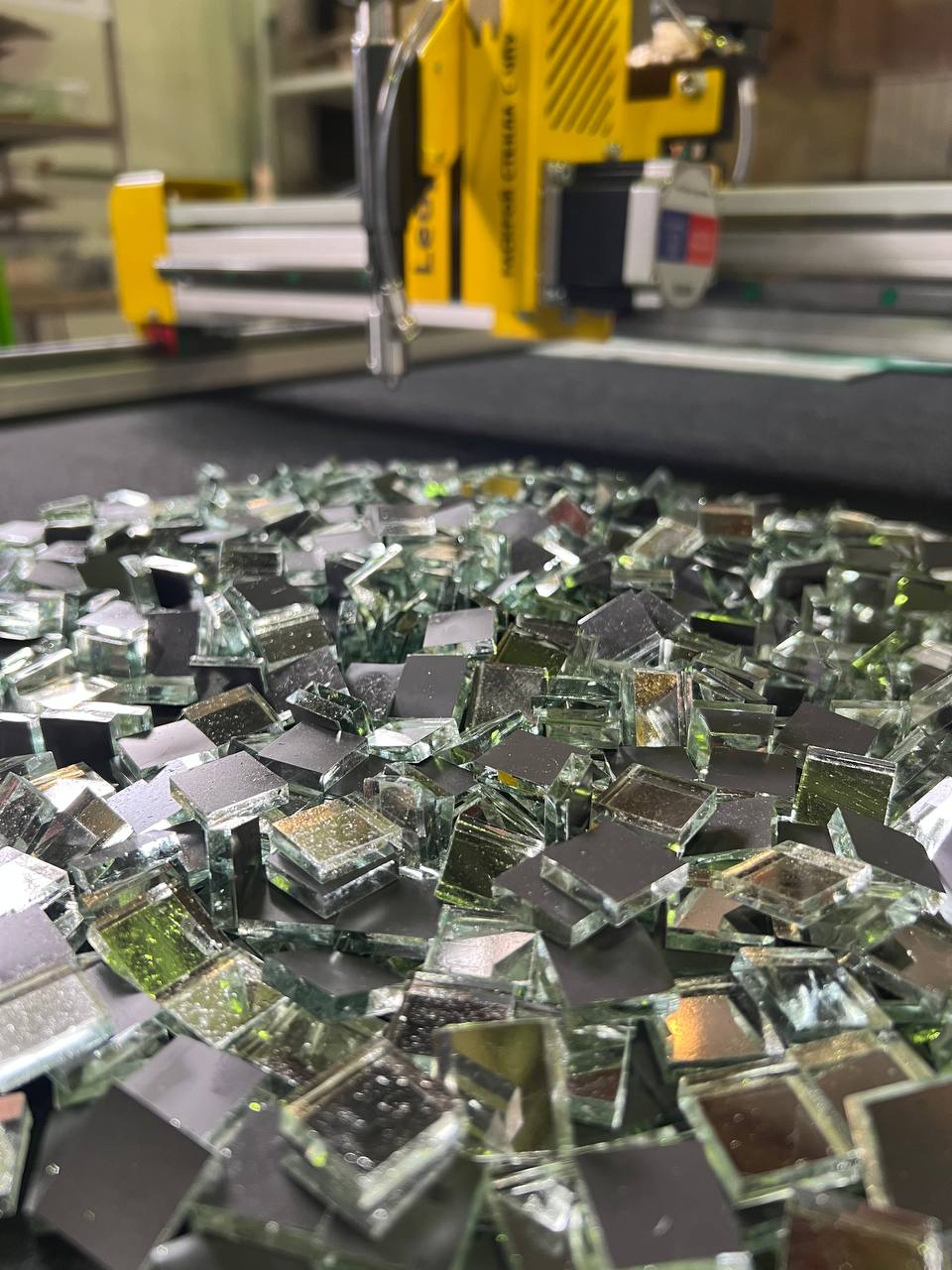

With this machine, you can achieve high-quality cuts of small pieces that are ideal for the production of various glass and mirror products.

One of the main advantages of this machine is its precision in glass and mirror cutting, with an accuracy of just 0.2mm. This allows for perfectly smooth edges, which is especially important in the production of mirror mosaics or other elements where each piece requires high precision.

The Leopard glass cutting table is available in two working area options: 900x1700mm or 900x900mm. This allows you to choose the option that is most convenient for your production needs.

Another advantage is the cutting speed of up to 15 meters per minute. Thanks to this, you can quickly and efficiently perform all the necessary glass and mirror cutting operations.

Additionally, this machine is equipped with an additional option - the installation of a film cutting head. This allows it to be used not only for working with glass but also with films (ORACAL / ORAJET) that need to be cut precisely and with quality.

Leopard glass cutting machines are in high demand among manufacturers of faceted elements, watchmakers, and design agencies. It has become an integral part of their production cycle, allowing them to quickly and accurately perform all the necessary glass and mirror cutting operations.

The Leopard glass cutting machine is an efficient and budget-friendly solution for manufacturers working with small glass and mirror details. It allows for perfectly smooth cuts, boasts high cutting speeds, and offers an additional option for working with film.

SHERHAN CM 1828 GLASS CUTTING MACHINE

The SHERHAN CM 1828 glass cutting machine is an industrial solution for producing high-quality glass and mirror products.

The SHERHAN CM 1828 glass cutting table allows for cutting materials ranging from 2 to 19mm in thickness with high precision and speed, making it an ideal choice for production tasks of any complexity.

One of the main advantages of this machine is its working area size of 1800x2800mm, which allows it to process large-sized glass and mirrors (sheets of glass and mirrors of 1800x2600mm, 1605x2550mm).

The SHERHAN CM 1828 CNC glass cutter is equipped with a laser glass position scanning system, which helps accurately determine its position on the cutting machine's work area.

The industrial glass cutting machine also features an air cushion that allows for easy movement of the glass across the cutting machine's work area.

An optimization system for up to three sheets is also included in the standard delivery package, ensuring optimal productivity when working with glass in large volumes.

The control panel of the machine is user-friendly and easy to use, and is capable of accepting files in DXF and G-code formats.

A library of ready-made templates for quick creation of cutting layouts and a template scanning system for glass cutting significantly simplify the production process.

The SHERHAN CM 1828 glass cutting machine has high performance capabilities, allowing for material processing speeds of up to 90m/min. This significantly speeds up the cutting process and increases the efficiency of the production cycle. The cutting accuracy is 0.15mm, ensuring perfectly straight cuts and precise dimensions of the product.

Among the additional options for the machine are:

- The Edit Way program (local version), which allows for optimization of up to 100 sheets;

- The glass breaking system along the long side is also available as an option.

Creating cutting layouts and uploading them to the machine can be done in several ways depending on the user's preferences and capabilities. You can upload cutting layouts from an Excel file, create them in Corel or AutoCAD, or use ready-made templates from the library.

The SHERHAN CM 1828 glass cutting machine is a high-quality industrial solution for producing any glass and mirror products. It offers high precision, productivity, and user-friendliness thanks to its thoughtful design and additional options.

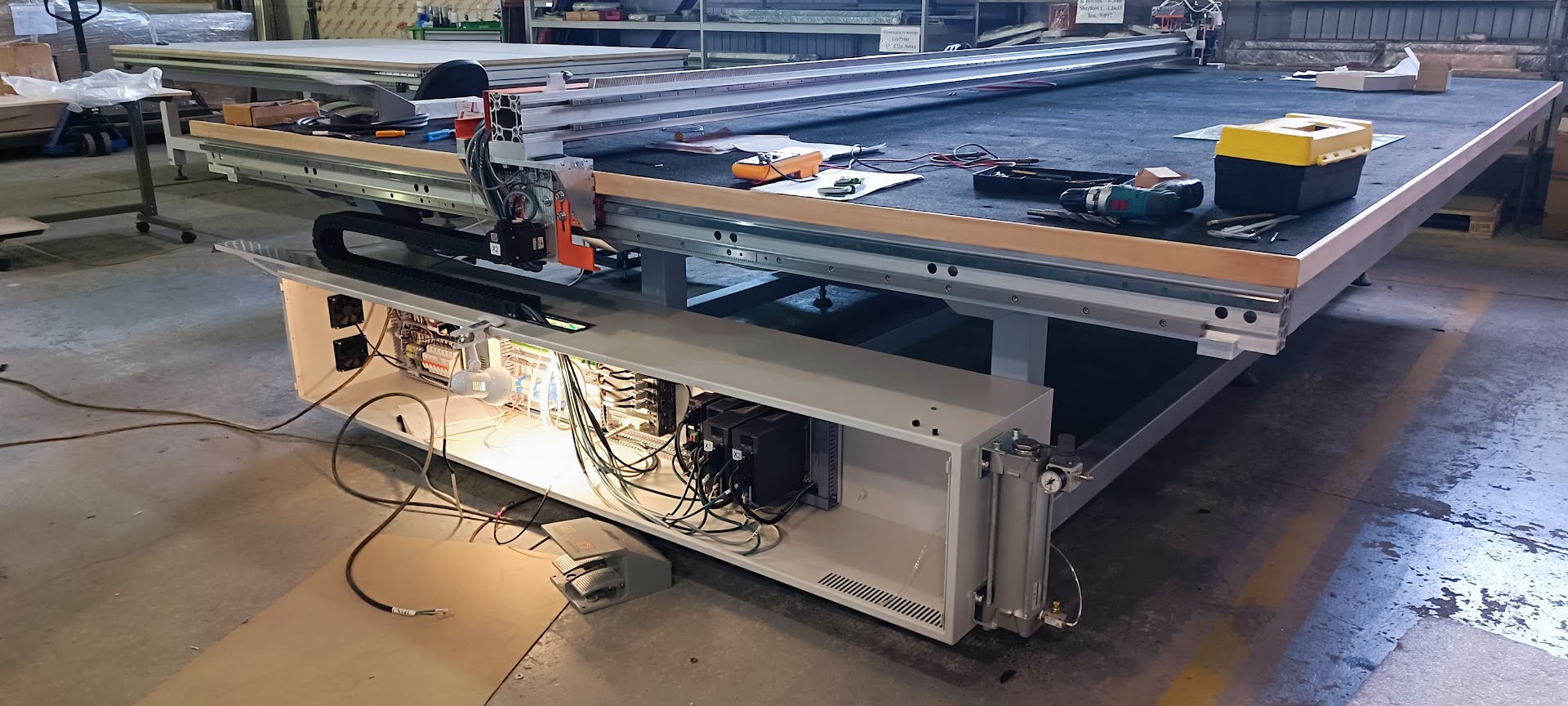

GLASS CUTTING MACHINE SHERHAN CM (Cutting machine) 2633

The SHERHAN CM (Cutting Machine) 2633 glass cutting equipment is an industrial solution designed for cutting and breaking glass and mirrors from 3 to 19mm in thickness. One of the main features of this machine is its integrated loading system, which allows for working with sheets measuring 2250x3210mm and 2550x3210mm.

The working area of the SHERHAN CM 2633 glass cutting table is 2600x3300mm, making it an optimal choice for large-scale production tasks.

The standard configuration of the SHERHAN CM 2633 cutting machine includes:

- A laser glass position scanning system (camera), which maximizes the accuracy of positioning the glass on the cutting machine's work area;

- An air cushion that allows for easy movement of the glass across the machine's work area, as well as onto glass and mirror breaking tables;

- An integrated optimization system for up to three sheets, suitable for serial production;

- A user-friendly controller that accepts DXF and G-code file formats;

- A library of ready-made templates for quick creation of cutting layouts.

If required, a template scanning system for glass cutting can also be used.

The cutting performance of the machine reaches up to 180m/min (recommended working speed is 90-120m/min), with a cutting accuracy of 0.15mm.

For more complex glass cutting tasks, the Edit Way program (local version) is available, allowing for optimization of up to 100 sheets. This is an optimal option if you need to cut many unique sizes of glass and mirrors.

The machine is also equipped with a glass breaking system along the long and short sides.

Creating cutting layouts and uploading them to the machine can be done in several ways. You can load cutting layouts for straight-line glass and mirror cutting from an Excel file or create a cutting layout in Corel or AutoCAD. It is also possible to create and optimize cutting layouts directly at the computer or in the office, depending on your needs.

The SHERHAN CM 2633 glass cutting machine is an optimal solution for large-scale production tasks. It is equipped with everything necessary for precise and fast cutting of glass and mirrors. The presence of an optimization system allows for significant reduction in material costs, and the integrated loading system provides convenience and speed in operation.